-

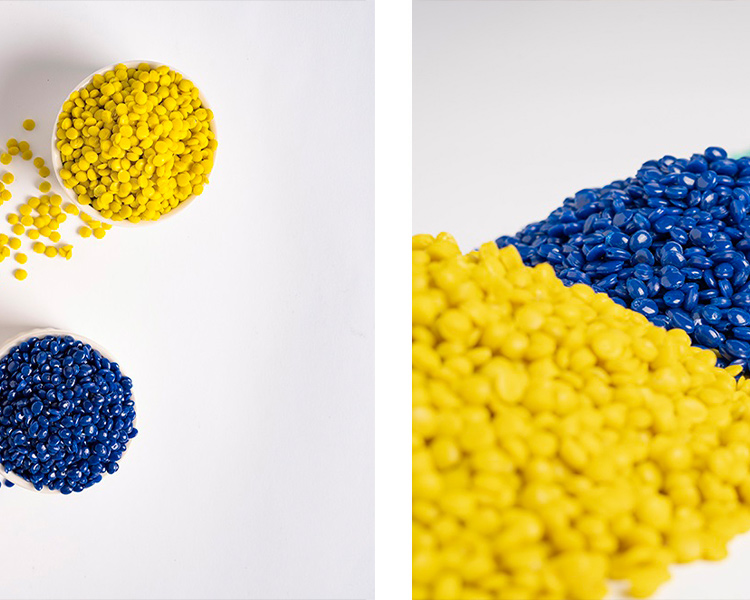

Eco Materials

-

Quality Impact

-

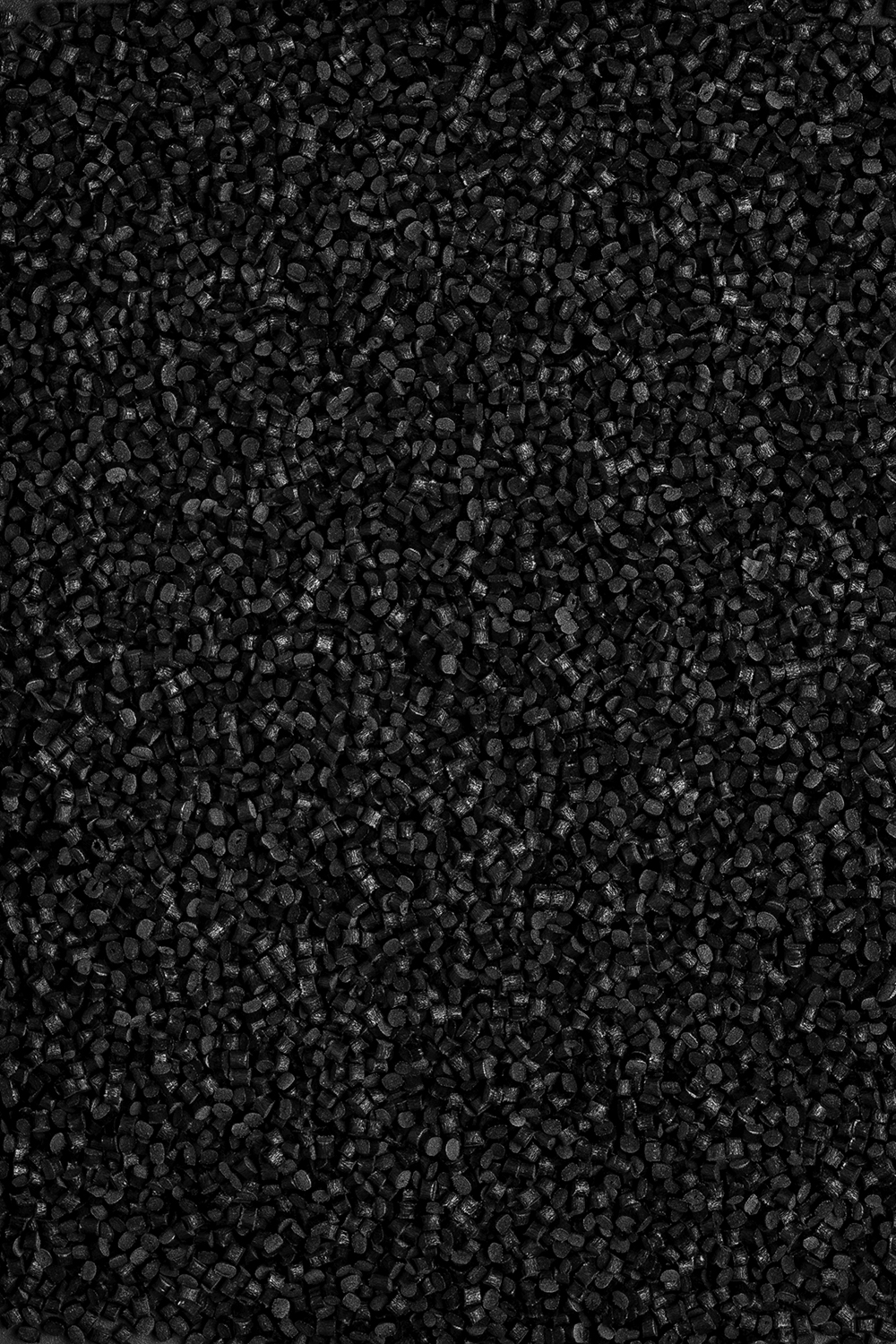

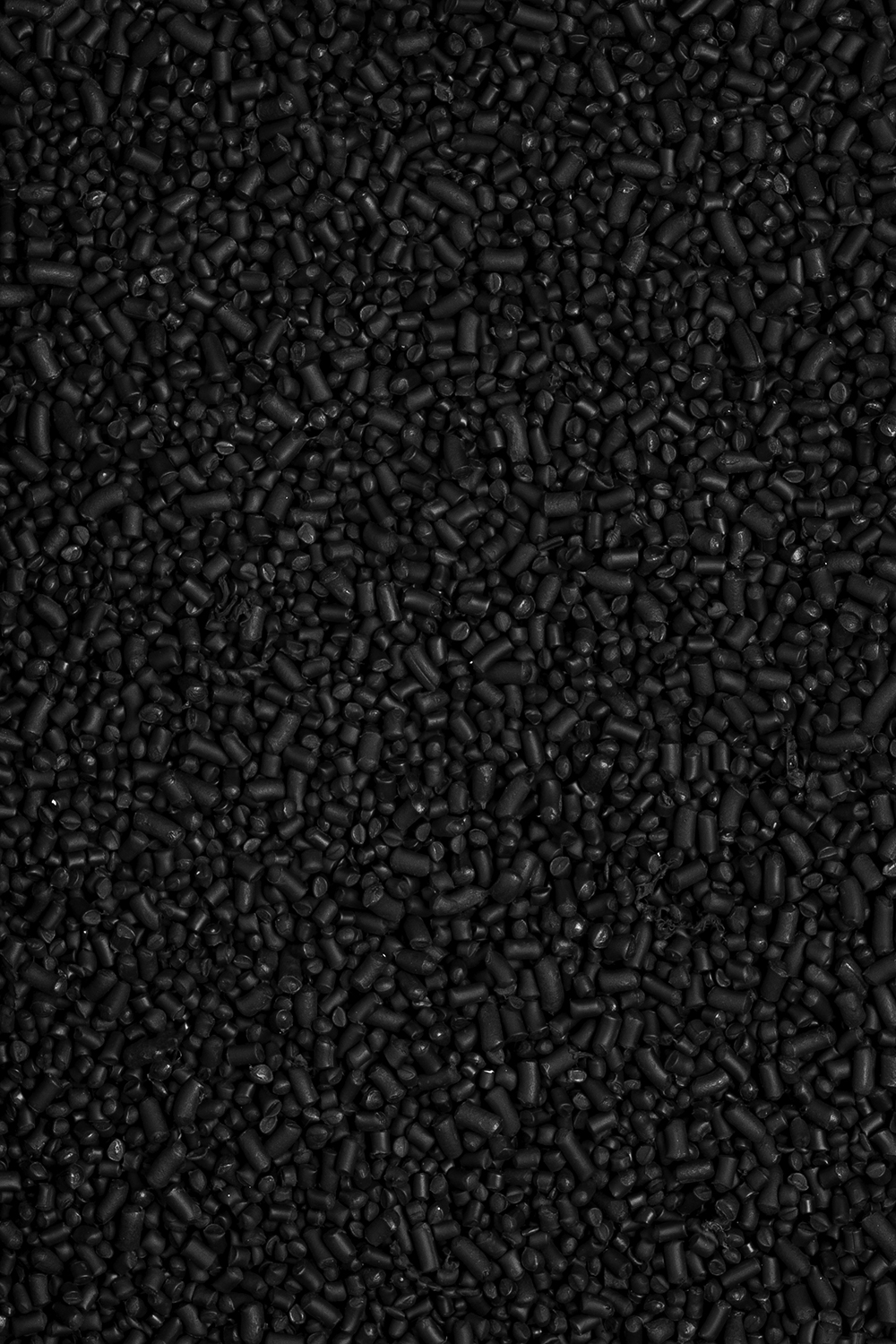

Raw Material

Green solutions in raw materials.

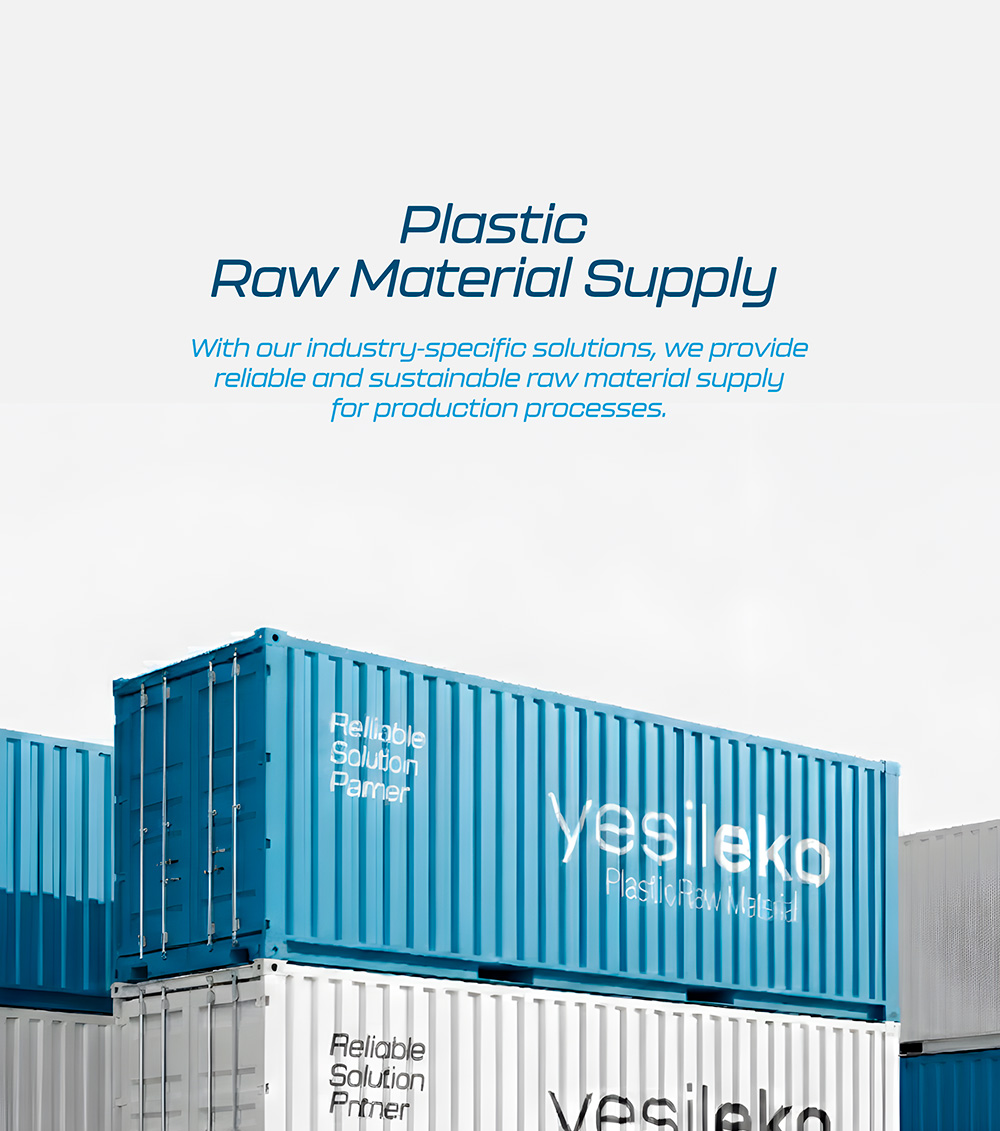

Yeşileko is a reliable and innovative supplier specialized in plastic raw materials. With our experienced team, we provide customer-oriented solutions both domestically and internationally.

In addition to the raw materials we process at our own facilities, we supply original and recycled polymers, colorants, and additives sourced from around the world. Our operations comply with SEDEX standards and the Global Recycle Standard (GRS), ensuring sustainable and responsible supply chains.

Thanks to our widespread warehouse network across Turkey and our robust logistics infrastructure, we respond to customer demands quickly, with high quality and competitive pricing.

Yeşileko continues its journey with a dynamic, forward-thinking approach—committed to sustainability, social responsibility, and adding value to the plastics industry.

Enhance your production with high durability, flexibility, and excellent processability.

Blackheads

In the Machine:

- The weight may be very high.

- It may have been closed for a long time.

- The hive may not have been cleaned properly.

- The correct nozzle may not have been used.

In the Mold:

- Runner with angular corners

In the Raw Material:

- It may contain mixed other materials.

- The other material inside may burn.

Solutions in Order:

- The machine should be cleaned with the correct material at the same temperature.

- It should be checked whether another material has mixed in.

- The runner entries and type should be checked.

- The filter perforation should be checked.

Air and Gas Bubbles

In the Machine:

- The injection pressure may be very low.

- The backflow valve may be faulty.

- The back pressure may be too long.

- The melting process may be too fast.

- Air may be trapped at the funnel inlet.

- Poor feeding may occur.

In the Mold:

- The mold temperature may be low.

- The mold gas outlet may be closed.

- The runner entry thickness of the part.

- It may go from thin to thick.

In the Raw Material:

- The material may not be able to withstand high temperatures.

Solutions in Order:

- The injection pressure and extrusion pressure should be increased.

- The back pressure should be increased.

- The mold temperature should be increased.

- The backflow valve should be checked.

- The mold air channel should be checked.

- The runner diameter should be increased.

Flow Marks

In the Machine:

- The injection speed may be too low or too high.

- The injection pressure may be too low.

- The extrusion pressure may be too low.

In the Mold:

- The mold temperature control is not good.

- The mold temperature at the runner entry may be too high.

- The mold may be too cold.

- The runner diameter may be too small.

- Incorrect runner entry.

- Incorrect hot runner system.

In the Raw Material:

- The material temperature may be low.

Solutions in Order:

- The injection speed should be adjusted.

- The possibility of unmelted material should be checked.

- The injection cavity should be checked.

Surface Burns (Diesel Effect)

In the Machine:

- The backflow valve may be faulty.

- The injection speed may be too fast or too high.

- The back pressure may be too high.

In the Mold:

- The air outlet may be closed.

- Burning due to sharp corners in the mold.

- The runner entry may be narrow.

In the Raw Material:

- The material may burn due to high temperature or may burn by friction due to low temperature.

Solutions in Order:

- The air intake channels should be checked for blockages.

- The injection speed should be reduced.

- The injection pressure should be reduced.

- Gradual injection should be tried.

- The heaters should be checked to ensure they are working properly.

- The screw speed should be reduced.

- The nozzle temperature should be reduced.

Optimizes your production processes with high efficiency and eco-friendly solutions.

Follow our blogs for the latest trends, developments, and tips in your industry.